The magnetic deburring machine is a device that uses magnetic force and abrasives for deburring. It can remove burrs, oxide scales and other bad surface defects on the surface of metal workpieces, and improve product quality and appearance. The principle of the deburring machine is to form a grinding force on the surface of the workpiece through the force between the magnetic force and the abrasive to remove burrs and other bad surfaces, so that the surface of the workpiece is smooth and clean.

The magnetic deburring machine has a wide range of applications and can be used for deburring of steel, aluminum, copper, stainless steel and other metal products. According to the different shapes and sizes of the processed workpieces, the structure of the deburring machine is also different, mainly including different types such as rotary type, translation type and magnetic needle type.

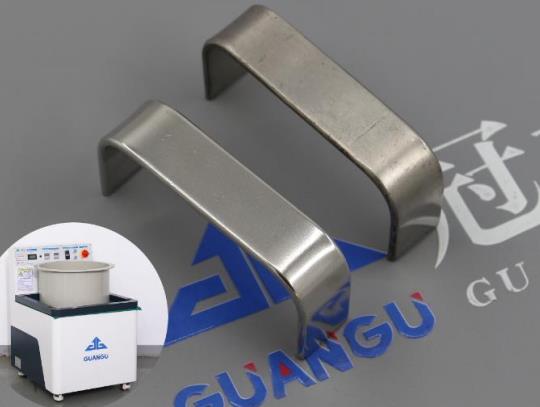

Magnetic needle type magnetic deburring machine is a common deburring equipment, it uses the principle of combination of magnetic force and abrasive, can be used for deburring and deburring of metal materials such as steel, copper, aluminum, stainless steel, die casting, forging surface treatment.

Magnetic deburring machine

The main features and advantages of the deburring machine are as follows:

- High density of magnetic needles: The equipment adopts high-density magnetic needles, which can form a uniform magnetic force field on the surface of the workpiece to achieve uniform grinding of the surface of the workpiece.

- Adjustable amount of abrasive: By adjusting the number of grinding steel needles, the precise control of the amount of abrasive can be realized to achieve a finer deburring effect.

- Wide range of application: the deburring machine is suitable for workpieces of different types and shapes, including flat plates, pipes, bars, profiled materials, etc.

- High efficiency and energy saving: The magnetic needle group and heating system of the equipment adopt energy-saving design, which can effectively save energy and improve the use efficiency of the equipment.

- Easy to operate: The equipment adopts PLC control system, which is easy to operate and can precisely adjust the grinding parameters to meet the processing requirements of different workpieces.

- Good treatment effect: Through the combination of magnetic force and abrasive, the equipment can remove burrs, oxide scales, welding spots and other bad surfaces on the surface of the workpiece, and improve the quality and appearance of the product.

It should be noted that when using a magnetic deburring machine, the appropriate grinding steel needle model should be selected according to the requirements and characteristics of the specific workpiece to achieve a better processing effect. At the same time, the operator should also pay attention to the safety operation rules of the equipment to ensure the safety of personal and equipment.

You must be logged in to post a comment.