Polishing is a processing method for the surface of titanium alloy pipes, which can make the surface smoother, increase the aesthetics and reduce the surface friction coefficient. Here’s how to polish titanium pipes:

Mechanical polishing: Mechanical polishing is a method of grinding and polishing the surface of titanium alloy pipes using machinery and equipment. The first step is to smooth the surface with a coarse grind, and then gradually change the grind until the desired finish is achieved. This polishing method is called mechanical polishing.

Electrolytic polishing: Electrolytic polishing is to use the titanium alloy pipe as the anode, and electrify it in the electrolyte to form an oxide film on the surface. Under specific electrolytic conditions, the formation and disappearance of the oxide film are alternately repeated, so as to achieve the polishing effect. This polishing method results in a very high surface finish.

Chemical polishing: chemical polishing is to achieve the polishing effect by adding specific chemical reagents to the polishing solution to make the surface of the titanium alloy chemically react under high temperature and high pressure conditions. This polishing method is effective for special shapes or small pipes.

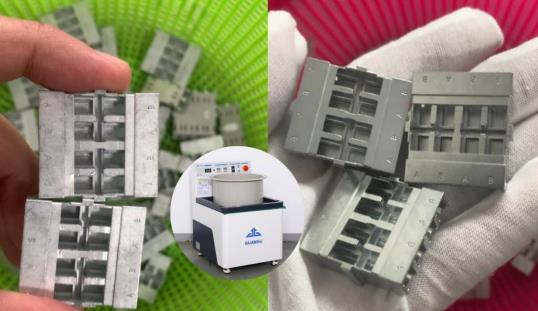

Energy-saving and environment-friendly magnetic grinding machine to remove knife marks

Titanium alloy pipe fittings refer to pipes, elbows, tees, reducers and other shapes made of pure titanium or titanium alloy. Its main features are light weight, high strength, good high temperature oxidation resistance, and strong corrosion resistance. Therefore, it has been widely used in some highly demanding fields. The following are some application scenarios of titanium alloy pipe fittings:

Aerospace field: Titanium alloy pipe fittings are widely used in the aerospace field to manufacture engines, aircraft systems, missiles and other structural materials due to their light weight, high strength, high temperature resistance, and strong oxidation resistance.

Magnetic polishing machine for special-shaped parts

Medical industry: Titanium alloy pipe fittings are widely used in the medical industry due to their excellent biocompatibility, such as artificial joints, dental implants, surgical instruments, etc., which can effectively avoid problems such as allergic or rejection reactions with the human body.

Chemical industry: Titanium alloy pipe fittings are widely used in the chemical industry due to their good corrosion resistance, such as the manufacture of acid-base containers, lined pipes and other equipment, which can effectively solve corrosion problems in harsh environments such as high temperature and high pressure, strong acid and strong alkali.

Automobile manufacturing industry: Due to its light weight and high strength, titanium alloy pipe fittings are used in the automobile manufacturing industry, such as manufacturing automobile exhaust pipes and other components, reducing the weight of the car body, and improving the performance and fuel economy of the car.

You must be logged in to post a comment.