In the industrial field, the issue of burrs has always troubled production personnel. Burrs not only affect the quality and accuracy of the workpiece, but may also cause obstacles to subsequent processing and assembly. In order to solve this problem, magnetic deburring machines have emerged. This article will delve into the principle, application scenarios, usage methods, future development, and impact on the added value of magnetic deburring machines.Magnetic deburring machine: a sharp tool for increasing the added value of workpieces.

1、 Deburring principle

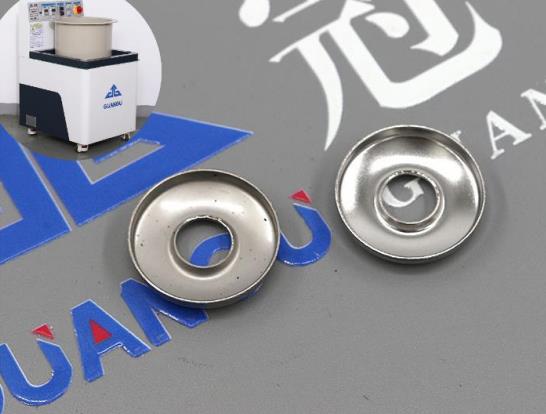

The magnetic deburring machine utilizes the principle of magnetic field to fix the workpiece through the magnetic force generated by the magnetic field, and utilizes the characteristics of magnetic adsorption to remove small burrs on the surface of the workpiece. The magnetic deburring machine is easy to operate and can efficiently remove burrs on the surfaces of various metal and non-metallic materials, while also improving the surface quality of the workpiece.

2、 Application of Magnetic Deburring Machine

Mechanical manufacturing: In the field of mechanical manufacturing, magnetic deburring machines can be widely used for deburring treatment of various parts, such as gears, bearings, pistons, etc. After being processed by a magnetic deburring machine, the surface quality and accuracy of these parts are improved, thereby increasing the added value of the product.

Electronics industry: In the electronics industry, magnetic deburring machines are suitable for deburring various types of circuit boards, electronic components, and semiconductor materials. By deburring, the stability and reliability of electronic equipment can be improved, and the failure rate can be reduced.

Automotive industry: In the automotive industry, magnetic deburring machines play an important role in surface treatment of key parts such as engines, chassis, and brake systems. By deburring, the safety performance and reliability of automobiles can be improved.

3、 Usage and precautions of magnetic deburring machine

When using a magnetic deburring machine, the first step is to select a suitable magnetic deburring head based on the material, shape, and deburring requirements of the workpiece. Then, adjust the distance between the deburring head and the workpiece to ensure that the magnetic force can effectively absorb the workpiece without causing damage to the workpiece. During the operation process, it is necessary to keep the equipment clean, regularly check the operating status of the equipment, and promptly handle any abnormalities found.

4、 The Future Development of Magnetic Deburring Machines

With the continuous development of technology, magnetic deburring machines will be applied in more fields. In the future, magnetic deburring machines may develop towards intelligence, efficiency, and precision. For example, by introducing robot technology, automated and intelligent deburring processing can be achieved; By improving magnetic field technology, improve deburring efficiency and processing quality; By developing more precise magnetic deburring tips, finer burrs can be processed.

5、 Conclusion

Magnetic deburring machine, as an advanced surface treatment equipment, has been widely used in many fields such as mechanical manufacturing, electronics industry, and automotive industry. It utilizes the principle of magnetic field to efficiently remove small burrs on the surface of the workpiece, improving the surface quality and accuracy of the workpiece, and thereby increasing the added value of the product. In the industrial field, the application of magnetic deburring machines is gradually expanding, and in the future, it will demonstrate its huge potential in more fields. Therefore, we should pay attention to the development trends and application prospects of magnetic deburring machines to better meet the needs of industrial production, improve product quality and competitiveness.

You must be logged in to post a comment.