There are mainly the following methods for deburring metal flat gaskets:

Manual grinding: For small batches of metal flat gasket deburring, manual grinding can be used. First, the metal flat gasket needs to be cleaned before grinding, then use a metal file or sandpaper to smooth the burrs, and finally use a fine emery cloth to wipe the surface to make it smoother.

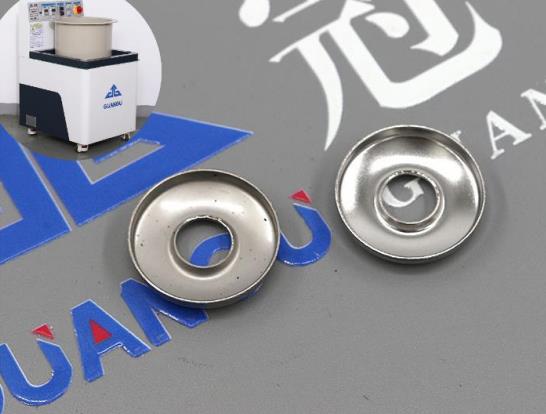

Mechanical polishing: For the deburring of metal flat gaskets in large quantities, mechanical polishing can be used. This method can automatically complete the grinding and polishing of metal flat gaskets by machine, which can greatly improve efficiency and precision. During polishing, proper abrasive and polishing pastes are used to ensure a smooth, burr-free metal surface.

Passivation: Another common method of deburring metal flat gaskets is passivation. Passivation is a chemical treatment that reduces or eliminates burrs by controlling the passive film on the metal surface. During the passivation process, the metal flat gasket needs to be soaked in an acidic solution for a period of time, usually tens of minutes. After treatment, the metal flat gasket needs to be rinsed with water, then dried and packaged.

The above are some common methods of deburring metal flat gaskets. Before deburring, it is necessary to understand the characteristics and requirements of metal materials, so as to choose suitable deburring methods and tools. At the same time, when deburring, it is necessary to have a good sense of safety, abide by relevant operating procedures and safety measures, and avoid accidents.

Magnetic grinding machine polishing, free sample

Metal deburring needs to pay attention to the following points:

Safety measures: Safety should be taken when deburring metal. Use goggles, gloves, and other appropriate protective equipment to protect against splashes of metal or other substances.

Magnetic polishing machine batch processing, does not affect the accuracy of the workpiece

Cleaning Metal Surfaces: Before performing metal deburring, metal surfaces need to be cleaned for better detection and removal of burrs. Cleaning should use appropriate solvents and cleaning methods.

Choose the right tool: Choose the right tool based on factors such as metal type, size and shape of the burr. Tools that can cut, grind, stretch, or compress metal are usually used, such as metal files, sandpaper, hammers, and pliers.

Hold it steady: For smaller burrs, you need to keep your hand steady to avoid unnecessary cutting or abrasion.

Review the repaired metal: After metal deburring is complete, the repaired metal surface should be carefully inspected to ensure that burrs have been completely removed and no new problems have been introduced. This can be done by visual inspection or using a magnifying glass or microscope.

You must be logged in to post a comment.