Product description

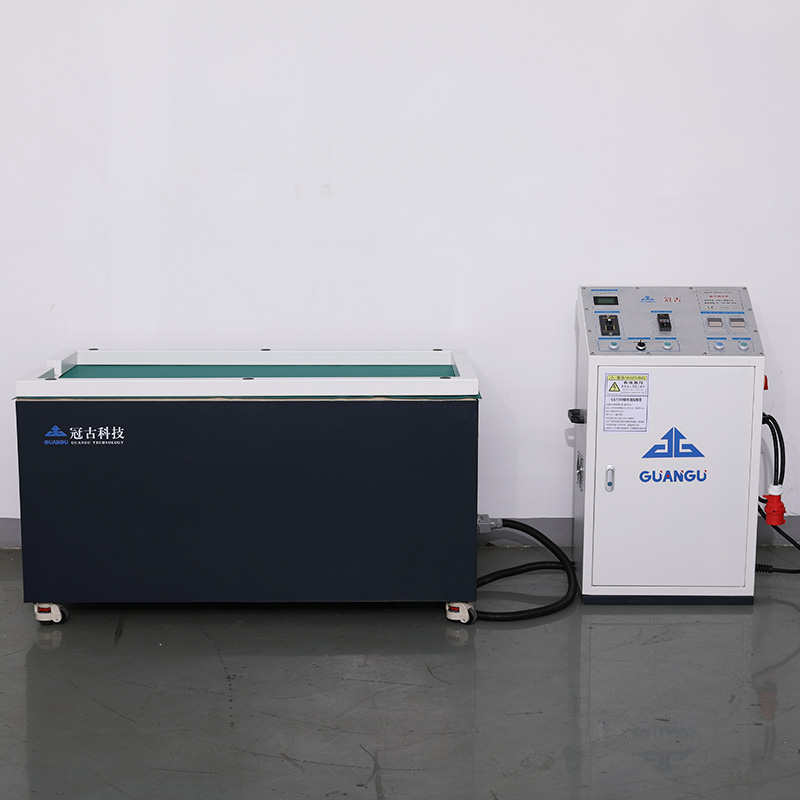

Dual station translational magnetic polishing machine GG1980:

External dimensions: 1980 * 720 * 1088

Grinding groove size: 1800 * 520mm (square barrel)

Power supply: AC380v

Motor power: 4kw * 2

Equipment weight: 580Kg

Grinding capacity: 40-60Kg

Operation mode: forward, reverse, and translation

Magnetic grinding steel needle: Made of imported SUS304 stainless steel, with a diameter of 0.2-2.0mm.

Grinding fluid: 100L

Motor speed: 1400 rpm

2 frequency converter control panels (Delta brand)

Magnetic Grinding and Magnetic Polishing Machine

Magnetic Grinding and Polishing Machine can be used to grind and polish various metal materials, non-metal materials, semiconductor materials and so on. In the field of metal processing, magnetic grinding and polishing machine can be used to grind and polish stainless steel, aluminum and other metals to remove surface imperfections and scratches and improve surface quality.

In the aerospace field, magnetic grinding and polishing machines can be used to grind and polish aircraft engine blades, turbine disks, and other high-precision parts to improve the precision and finish of the parts.

When using magnetic grinding and polishing machines, attention needs to be paid to selecting the appropriate type of magnetic grinding machine, suitable grinding materials and process parameters to ensure the effect and efficiency of grinding and polishing. At the same time, attention needs to be paid to safe operation to avoid machine failure and personnel injury.

Compared with ordinary grinding machine, magnetic grinding and polishing machine has higher grinding and polishing efficiency, which can remove surface scratches, imperfections and uneven parts faster and make the surface smooth, flat and shiny.

Magnetic polishing works by utilizing the principles of magnetism. When a magnetic substance such as iron powder or iron filings comes into contact with a magnetic field, it aligns itself with the field lines. This alignment causes the magnetic particles to rub against each other, creating friction and heat. This friction and heat cause the surface of the material being polished to become smooth and mirror-like.

The Benefits of Magnetic Polishing

Magnetic polishing offers several advantages over traditional polishing methods. First, it can achieve ultra-smooth surfaces with high precision and low surface roughness. This makes it ideal for applications where a high-quality finish is crucial, such as in the manufacture of high-performance electronics and optical components.

Second, magnetic polishing can be used on a wide range of materials, including non-magnetic materials such as glass, quartz, and plastics. This makes it a versatile polishing method that can be applied to a variety of industrial applications.

Finally, magnetic polishing is a clean process that produces minimal waste and minimal damage to the surface being polished. This makes it an environmentally friendly alternative to traditional polishing methods.

Reviews

There are no reviews yet.