Product description

Magnetic polishing machine GG8720

A magnetic polishing machine is a machine that uses magnetic force to polish the surface of a workpiece. Its working principle is to rotate the magnetic field through the rotation of the motor, and use the magnetic force to attract and rotate the workpiece. At the same time, the magnetic polisher machine can provide a certain pressure to the workpiece surface through the spring, so as to achieve the polishing effect. The polishing machine is mainly used for polishing stainless steel, aluminum and other non-magnetic materials.

The advantages of magnetic polishing machine are as follows:

Can do what traditional polishing machine can not do, such as holes, dead ends and other places, magnetic polishing machine can easily complete the deburring polishing cleaning de-oxidation and other roles.

Wide range of application, as long as the metal is not magnetic can be taken down.

In addition to oxidation speed, in addition to the oxidation effect is obvious, easy to use, no pollution and other advantages.

Does not damage the appearance of the workpiece, metal in the air after a period of time, it is simple to rust oxidation. The use of polishing machine can solve the problems of traditional rust removal process, making the metal surface smoother, while not causing damage to the metal surface.

Low cost, magnetic polisher machine grinding material stainless steel needle for semi-permanent grinding material, consumption is very low, the only consumables for grinding and polishing fluid.

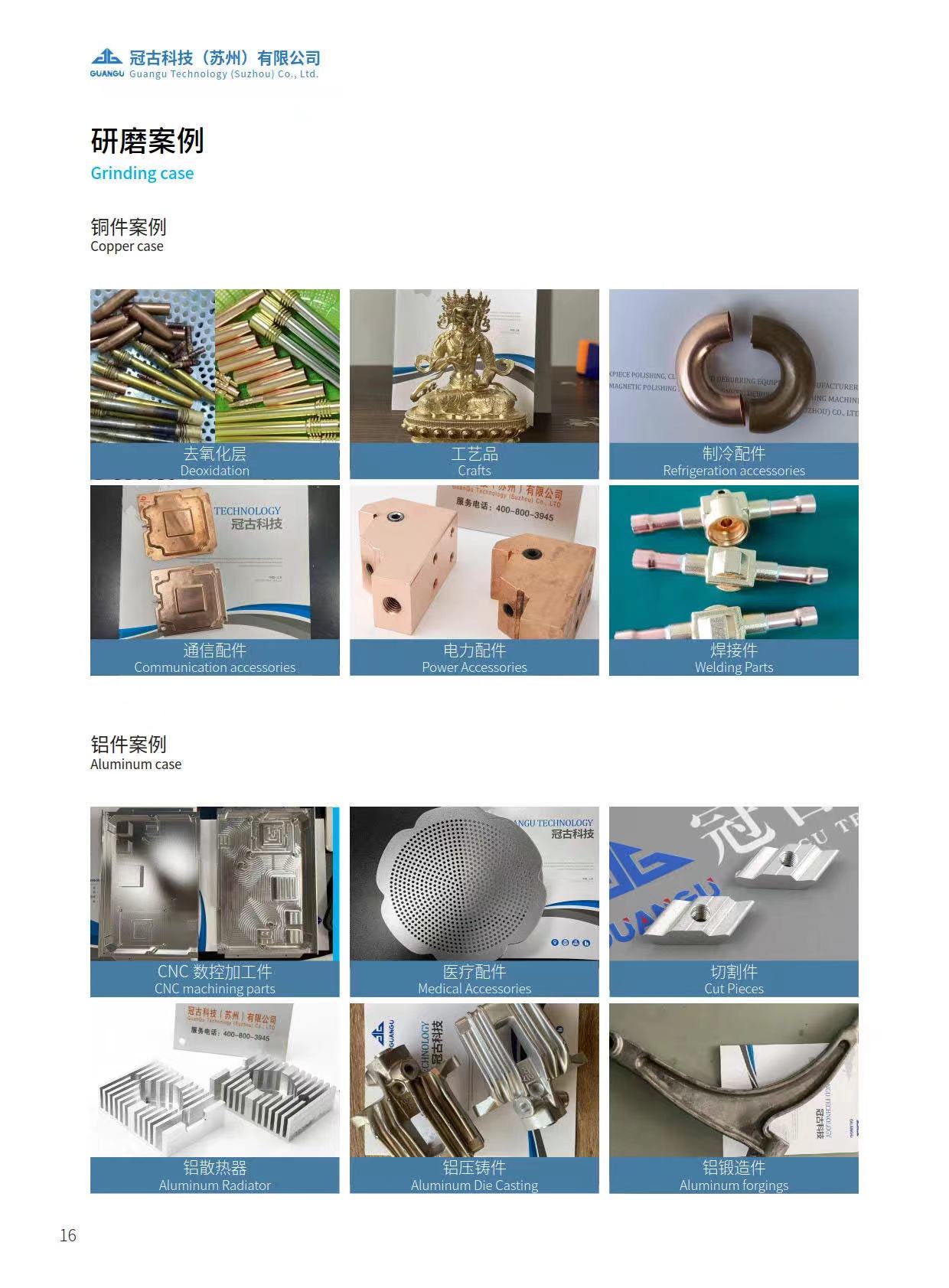

Copper polishing case

Aluminium polishing cases

Magnetic polisher has a wide range of applications and can be used to process workpieces made of various materials, such as stainless steel, aluminium, copper and other non-ferrous metal parts, as well as carbon steel, alloy steel and other ferrous metal parts. Processed parts can include precision hardware stamping parts, stainless steel parts, 304 stainless steel screws and nuts, magnesium and aluminium die casting parts, zinc and aluminium die casting parts, precision springs, shrapnel parts, electronic, computer, communication parts, walking heart, walking tool, CNC automatic lathe parts, aerospace, medical equipment parts, and so on.

Meanwhile, the magnetic polisher machine is suitable for different industries and scenarios, such as agricultural machinery, industrial manufacturing, aviation manufacturing, TV communication, nuclear energy utilisation and other fields. In addition, polishing machine is also widely used for polishing precision parts such as gold and silver jewellery, clothing accessories, precision spiral, medical equipment, instrumentation and other precision parts.

Stainless steel polishing case

Reviews

There are no reviews yet.