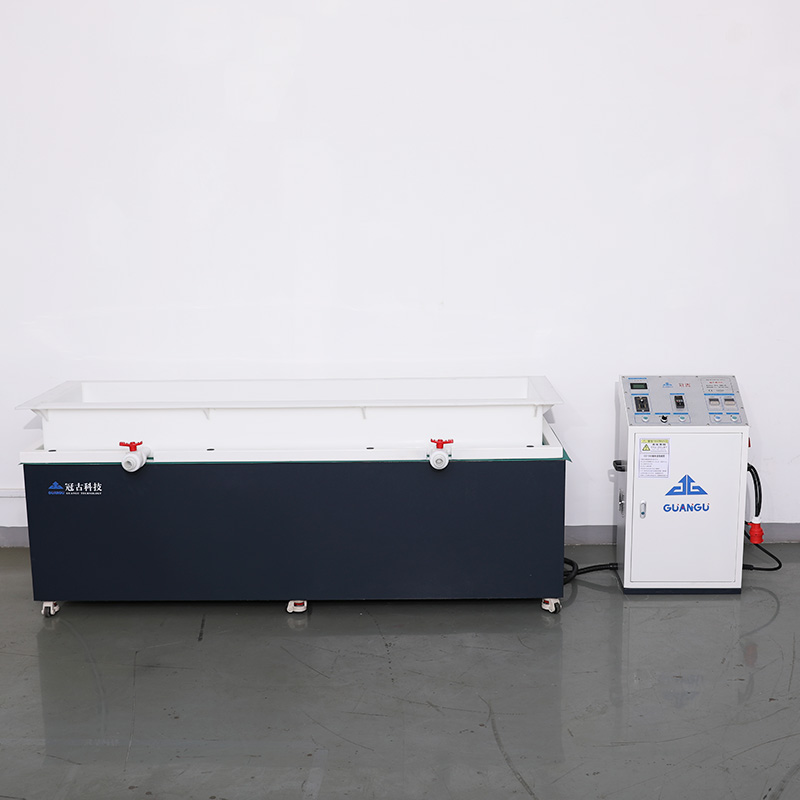

Magnetic polishing machine is a kind of mechanical equipment commonly used in metal surface processing, which uses magnetic force and abrasives for surface treatment. It is mainly composed of disks, magnetic materials, magnetic coils, abrasives, workpieces, etc.Principle of Magnetic Polishing

The magnetic disk is the main part of the magnetic polishing machine. It is usually made of steel or cast iron, which has high hardness and rigidity, and the surface needs to be flat and smooth. There is a magnetic coil inside the disk, which can generate a strong magnetic field through current excitation, so that the surface of the disk presents a uniform magnetic adsorption effect.

The magnetic material is a ferromagnetic material, which is usually used to cover the surface of the disk. It can make the workpiece magnetically adsorbed on the surface of the disk to ensure the intensive contact between the workpiece and the grinding disc, so as to realize cutting and polishing. Commonly used magnetic materials are steel, nickel, cobalt, ferrite and so on.

The magnetic coil is the core component of the magnetic polishing machine. Its function is to generate a strong magnetic field through current excitation, so that the surface of the disk presents a uniform magnetic adsorption effect. The magnetic coil is usually made of copper wire, which can generate a strong magnetic field after current excitation, and its size and distribution will affect the strength and uniformity of the magnetic adsorption effect.

Abrasives are key materials in magnetic polishing machines, and their function is to cut and polish the surface of workpieces. Commonly used abrasives include steel needles , etc. The size and hardness of abrasive particles will directly affect the processing effect and surface quality.

The workpiece is the item that needs to be processed in the magnetic polishing machine. It usually needs to be surface treated to improve the surface quality and processing accuracy, including removing surface burrs, grinding the surface, etc.

In general, the magnetic polishing machine is a surface treatment equipment based on magnetic force and abrasive materials, which has the advantages of high efficiency, high precision, and wide applicability, and is widely used in the field of metal processing, such as aviation, automobile, electronics, machinery and other industries Processing and surface treatment of metal parts, bearings, gears, tools and other parts.

The main advantages of magnetic polishing machine include:

- Efficient: The magnetic polishing machine has a fast and efficient processing speed, which can effectively improve the processing efficiency and production efficiency of the workpiece.

- High precision: The magnetic polishing machine can cut and polish the surface of the workpiece with high precision, which can effectively improve the surface finish and processing accuracy of the workpiece.

- Wide applicability: The magnetic polishing machine is suitable for surface processing of various metal materials, such as steel, copper, aluminum, magnesium, zinc and other metal materials.

- Simple operation: The operation of the magnetic polishing machine is very simple, only basic machine adjustments and abrasive replacements are required to complete the processing.

- Energy saving and environmental protection: the magnetic polishing machine does not need to use a large amount of coolant and lubricant during the processing, which can save energy and protect the environment.

In general, the magnetic polishing machine is a metal surface treatment equipment with high efficiency, high precision and wide applicability, which can effectively improve the surface quality and processing accuracy of the workpiece, and is widely used in the field of metal processing.

You must be logged in to post a comment.